Injection molding has emerged becoming a pivotal process in the realm of electronics manufacturing. Its ability to fabricate complex components with high precision and at competitive prices makes it an optimal choice for a wide range of applications. By leveraging state-of-the-art molding techniques, manufacturers can design intricate electronic enclosures, connectors, and other critical components with exceptional strength.

The injection molding process involves injecting molten plastic into a precisely engineered mold. Once the plastic cools and solidifies, it is ejected from the mold, yielding a finished component that meets stringent quality standards.

One of the main advantages of injection molding in electronics manufacturing is its ability to minimize production costs. The process allows high-volume production with minimal waste, resulting in significant cost savings. Moreover, injection molding provides a high degree of design flexibility, enabling manufacturers to shape components with intricate geometries and precise tolerances.

Furthermore, the use of specialized materials in injection molding allows for enhanced electrical insulation properties, providing reliable performance in electronic devices. The integration of these advantages makes injection molding a valuable tool for optimizing electronics manufacturing processes.

Fine Metal Fabrication: A Foundation for High-Performance Electronics

In the rapidly evolving landscape of electronics, where performance reigns supreme, the impact of precision metal fabrication cannot be underestimated. Metal components form the backbone of countless electronic devices, from compact sensors to powerful computing systems. The intricate designs demanded by modern electronics necessitate a level of accuracy that only skilled metal fabrication techniques can provide.

The process of precision metal fabrication involves a series of meticulous steps, comprising cutting, bending, welding, and finishing. These operations are executed with remarkable accuracy using state-of-the-art machinery.

Furthermore, the selection of alloys is vital to ensure that the final product meets the high requirements of high-performance electronics. Metals possess a unique combination of attributes such as conductivity, durability, and thermal resistance.

Streamlining FBA Operations for Electronic Products maximize

Selling electronic products on Amazon's platform can be a lucrative venture, but managing Fulfillment by Amazon (FBA) operations requires meticulous planning and optimization. A well-structured method to FBA can significantly impact your profitability in this competitive market.

Here are some key tips to streamline your FBA operations for electronic products:

* Meticulously research product demand and competition before listing your items on Amazon.

* Optimize your product listings with detailed descriptions, high-quality images, and relevant keywords to attract customer attention.

* Choose the most effective FBA shipping plan based on your product size, weight, and demand.

* Utilize inventory management software to track stock levels, forecast demand, and prevent stockouts or overstocking.

* Deliver excellent customer service by promptly responding to inquiries and resolving any issues.

By focusing on these methods, you can optimize your FBA operations for electronic products, leading to increased sales, improved customer satisfaction, and a more lucrative business on Amazon.

Injection Molding Techniques for Durable Electronics Enclosures

In the realm of electronics manufacturing, durability is paramount. Devices are constantly subjected to wear and tear, making robust enclosures crucial for their longevity. Injection molding has emerged as a leading technique for crafting durable electronics enclosures due to its exceptional robustness. This process involves injecting molten plastic into a precisely engineered mold, resulting in high-quality components with intricate details.

Manufacturers utilize various molding techniques to achieve optimal durability, including post-mold cooling, which helps to reduce internal stresses and enhance the strength of the enclosure. Furthermore, selecting high-performance engineering plastics with inherent resistance to impact, abrasion, and chemical degradation is essential for ensuring long-term performance.

- Additionally, incorporating reinforcing materials such as glass fibers or carbon fiber into the plastic matrix can significantly improve the enclosure's structural integrity.

- Moldflow analysis plays a critical role in predicting and mitigating potential defects, ensuring uniform wall thickness and stress distribution throughout the enclosure.

- Finally, by meticulously selecting materials, optimizing molding parameters, and implementing rigorous quality control measures, manufacturers can produce durable electronics enclosures that survive demanding operational environments.

Precision Machining for Complex Electronic Components

The development of electronics has driven a requirement get more info for increasingly complex and miniaturized components. This poses a challenge for manufacturers who must create these intricate parts with high accuracy. Metal fabrication serves a critical role in this system, enabling the construction of components with {complexdesigns and tight tolerances.

- Substrates such as aluminum, copper, and stainless steel are frequently used in metal fabrication for electronics due to their mechanical properties.

- Processes like laser cutting, etching, and milling allow for the production of intricate shapes

- Automation has transformed metal fabrication, enhancing efficiency and detail

The ability to fabricate complex electronic components from metal is fundamental for a wide range of industries, including aerospace, automotive, and telecommunications. As technology advances, the demands on metal fabrication will continue to grow.

Utilizing FBA Strategies for Successful Electronics Sales and Fulfillment

To thrive in the competitive world of electronics sales on Amazon, mastering FBA strategies is paramount. By optimizing your FBA strategy, you can boost sales, optimize fulfillment processes, and foster a loyal customer base. Begin by conducting thorough market research to pinpoint high-demand electronics niches with low competition. Develop compelling product listings with detailed descriptions, high-quality images, and competitive pricing. To lure customers, consider running targeted Amazon advertising campaigns and leveraging influencer marketing to promote your products.

- Utilize Amazon's Brand Registry to boost brand visibility and protect your intellectual property.

- Track inventory levels closely to avoid stockouts and fulfill orders promptly.

- Offer exceptional customer service by responding to inquiries efficiently and addressing any issues courteously.

Mr. T Then & Now!

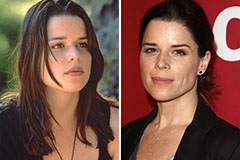

Mr. T Then & Now! Neve Campbell Then & Now!

Neve Campbell Then & Now! Michael Oliver Then & Now!

Michael Oliver Then & Now! Danielle Fishel Then & Now!

Danielle Fishel Then & Now! Ricky Schroder Then & Now!

Ricky Schroder Then & Now!